Holes And Notches

HOLES AND NOTCHES

Tecnoglass offers hole-drilling capabilities starting at 7 mm thickness.

Maximum Number of Holes

Any given lite of glass has a maximum capacity of ten (10) holes.

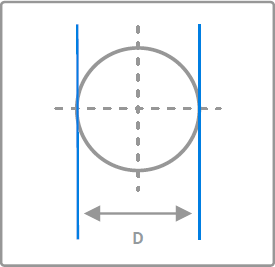

Guidelines for Hole Dimensions

Minimum diameter: Circular holes must have a diameter of at least 1/16″ greater than the thickness of the glass, with 1/4″ (6 mm) being the smallest hole allowed.

Maximum diameter: The maximum diameter of a hole cannot be more than 1/3 the narrowest dimension of the glass.

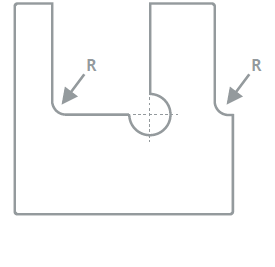

In the case of any holes that are non-circular or have straight edges, fillets are required in the corners. A fillet is a rounded corner from which the straight edge emerges. The radius of the fillet must be equal to 5/16″.

| Inches | |

|---|---|

| Glass Thickness |

D=Minimum Diameter |

| 3/16 | 1/4 |

| 1/4 | 5/16 |

| 5/16 | 3/8 |

| 3/8 | 7/16 |

| 1/2 | 9/16 |

| 5/8 | 11/16 |

| 3/4 | 13/16 |

| Milimeters | |

|---|---|

| Glass Thickness |

D=Minimum Diameter |

| 5 | 7 |

| 6 | 7 |

| 8 | 8 or more |

| 10 | 10 or more |

| 12 | 12 or more |

| 16 | 16 or more |

| 19 | 19 or more |

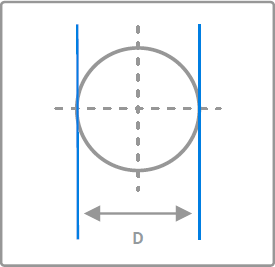

Guidelines for Minimum Glass Width with Holes

To be adequately tempered, any glass containing holes must have a minimum width of 8”. This and all other requirements, such as the dimensions of holes, their location and their spacing, must be met simultaneously.

| Inches | |

|---|---|

| Glass Thickness |

Minimum Width |

| 1/8 | 8 |

| 5/32 | 8 |

| 3/16 | 8 |

| 1/4 | 8 |

| 5/16 | 8 |

| 3/8 | 8 |

| 1/2 | 8 |

| 5/8 | 8 |

| 3/4 | 8 |

| Milimeters | |

|---|---|

| Glass Thickness |

Minimum Width |

| 3 | 203 |

| 4 | 203 |

| 5 | 203 |

| 6 | 203 |

| 8 | 203 |

| 10 | 203 |

| 12 | 203 |

| 16 | 203 |

| 19 | 203 |

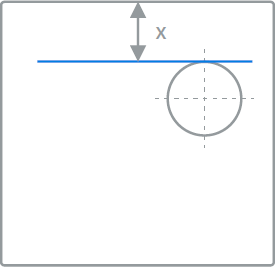

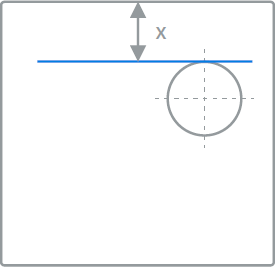

Guidelines for Hole Spacing

The distance from any edge of glass to the nearest point on the rim of the hole (x) must be twice the thickness of the glass.

| Inches | |

|---|---|

| Glass Thickness |

X=Minimum Width |

| 3/16 | 3/8 |

| 1/4 | 1/2 |

| 5/16 | 5/8 |

| 3/8 | 3/4 |

| 1/2 | 1 |

| 5/8 | 1-1/4 |

| 3/4 | 1-1/2 |

| Milimeters | |

|---|---|

| Glass Thickness |

X=Minimum Width |

| 5 | 10 |

| 6 | 12 |

| 8 | 16 |

| 10 | 19 |

| 12 | 25 |

| 16 | 32 |

| 19 | 38 |

The distance between holes must be twice the thickness of the glass.

The distance between holes must be 10 mm (3/8″) or twice the thickness of the glass, whichever is greater.

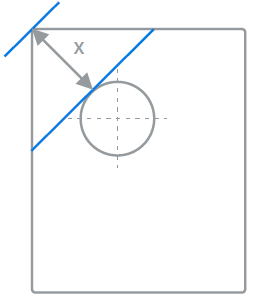

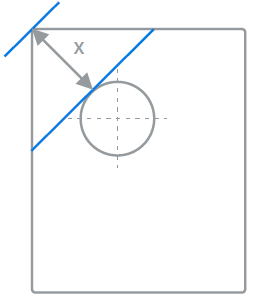

Guidelines for Holes Placement Near Glass Corners

Holes near glass corners must be located so that the nearest edge of the hole is at least 4 times the thickness of the glass from the tip of the corner when the corner is 90° or more.

| Inches | |

|---|---|

| Glass Thickness |

X=Minimum Width |

| 3/16 | 1-7/32 |

| 1/4 | 1-5/8 |

| 5/16 | 2-1/32 |

| 3/8 | 2-7/16 |

| 1/2 | 3-1/4 |

| 5/8 | 4-1/16 |

| 3/4 | 4-7/8 |

| Milimeters | |

|---|---|

| Glass Thickness |

X=Minimum Width |

| 5 | 20 |

| 6 | 24 |

| 8 | 32 |

| 10 | 40 |

| 12 | 48 |

| 16 | 64 |

| 19 | 76 |

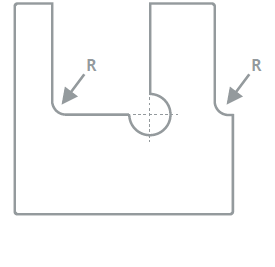

Notches

Using our Z. Bavelloni CNC Machine, Tecnoglass can supply you with more options for custom enhancements to monolithic glass. Please refer to the following guidelines when requesting your specially fabricated glass products.

Guidelines for Notches and Cutouts

Fillets on the corners are required in order to provide you with notches and cutouts, and their radius must be equal to 5/16”. As mentioned previously, a fillet is a rounded corner from which the straight edge emerges.

| Inches | |

|---|---|

| Glass Thickness |

X=Minimum Width |

| 3/16 | 1/2 |

| 1/4 | 1/2 |

| 5/16 | 1/2 |

| 3/8 | 1/2 |

| 1/2 | 1/2 |

| 5/8 | 5/8 |

| 3/4 | 3/4 |

| Milimeters | |

|---|---|

| Glass Thickness |

Minimum Radius |

| 5 | 8 |

| 6 | 8 |

| 8 | 8 |

| 10 | 8 |

| 12 | 8 |

| 16 | 8 |

| 19 | 8 |

Any fabricated glass products ordered with holes, notches or cutouts must be heat-treated. These cutouts create stress in the glass, and therefore annealed glass products cannot support notches and cutouts. The following fabrication limitations also apply to notch and cutout requirements:

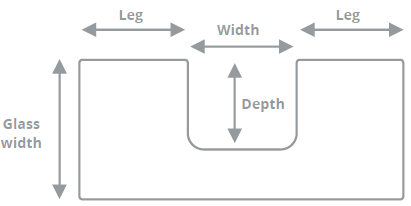

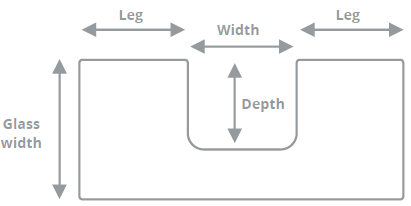

Fabrication Limitations

- The depth or width of the notch or cutout cannot have a dimension larger than 1/3 of the narrowest dimension of the lite.

- The leg length must be more than the depth of the notch.

- The leg length must be at least 3″.

- The depth of the notch must be less than the width.

- The inside corner(s) must have a radius equal to 5/16″ (8 mm).